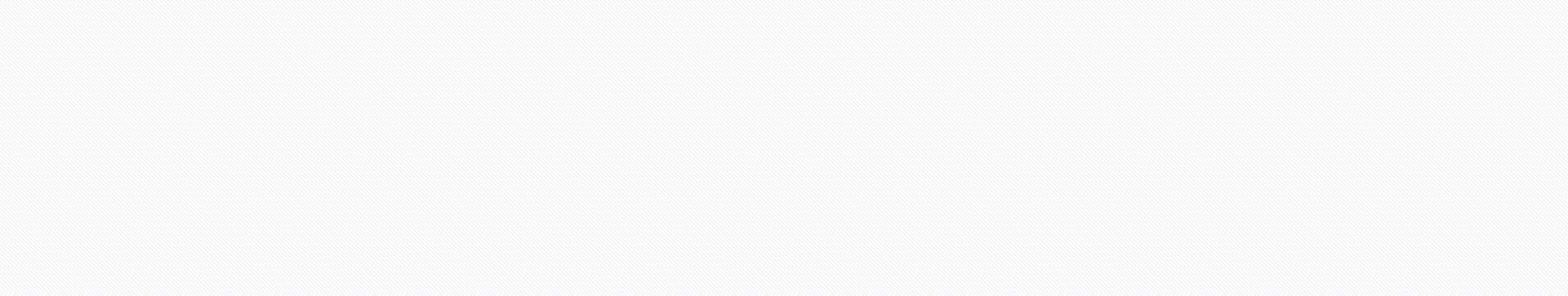

PATENTED AUTOCLAVE TECHNOLOGY

We build some of the world's largest autoclaves that are approved for the stringent requirements of the aviation industry.

Sistem Teknik specializes in the production of autoclaves for curing fiber and reinforced honeycomb matrix composite materials. We guarantee 21 bar and 450 °C operating values for the production of thermoset and thermoplastic composite materials because we have built some of the world’s largest autoclaves. P 355GH high temperature carbon steel is used in autoclave bodies that are designed in accordance with the AD 2000 Code standard.

Autoclaves For Composites

We can monitor the liquid, gel, and hardening phases of the resin in real time for both composite autoclaves and curing ovens when we use the Curing Performance Monitoring System. 1.5 °C temperature tolerance can be easily provided during operation with the patented semi-axial fan design we developed for autoclaves.

Sistem Teknik’s autoclaves have become critical for the civil and military aviation and space sectors, as they are used in the production of the BOEING 787, AIRBUS A350, AIRBUS A330, JSF F35, SIKORSKY S-76, MH-60, BOMBARDIER, AGUSTA AW139, as well as domestic satellite production.

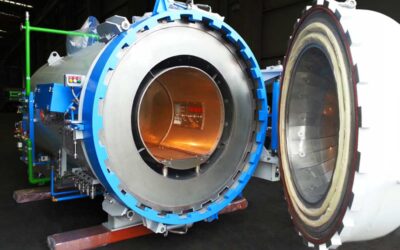

Curing Ovens For Composites

In accordance with specific customer requirements, Sistem Teknik develops composite curing technologies using the most advanced designs and analysis tools. Our extensive knowledge of composite systems enables us to meet the critical quality and durability requirements of the aerospace and defense industries. Our composite curing ovens (CCOs) meet AMS standards as well as those set by our customers.

Thermal curing processes for thermoset and thermoplastic materials can be performed economically in CCOs. Temperature uniformity is enhanced by multi-section vertical air flow systems. The part-based multi-point temperature measurement system controls and regulates the temperature of each part using a cutting-edge mathematical model-based control system.

The intricate quality reporting system monitors every detail of production and prevents any misalignment of quality requirements. Batch and recipe management systems, along with an integrated data redundancy system, are also intended to control every aspect of the curing process.