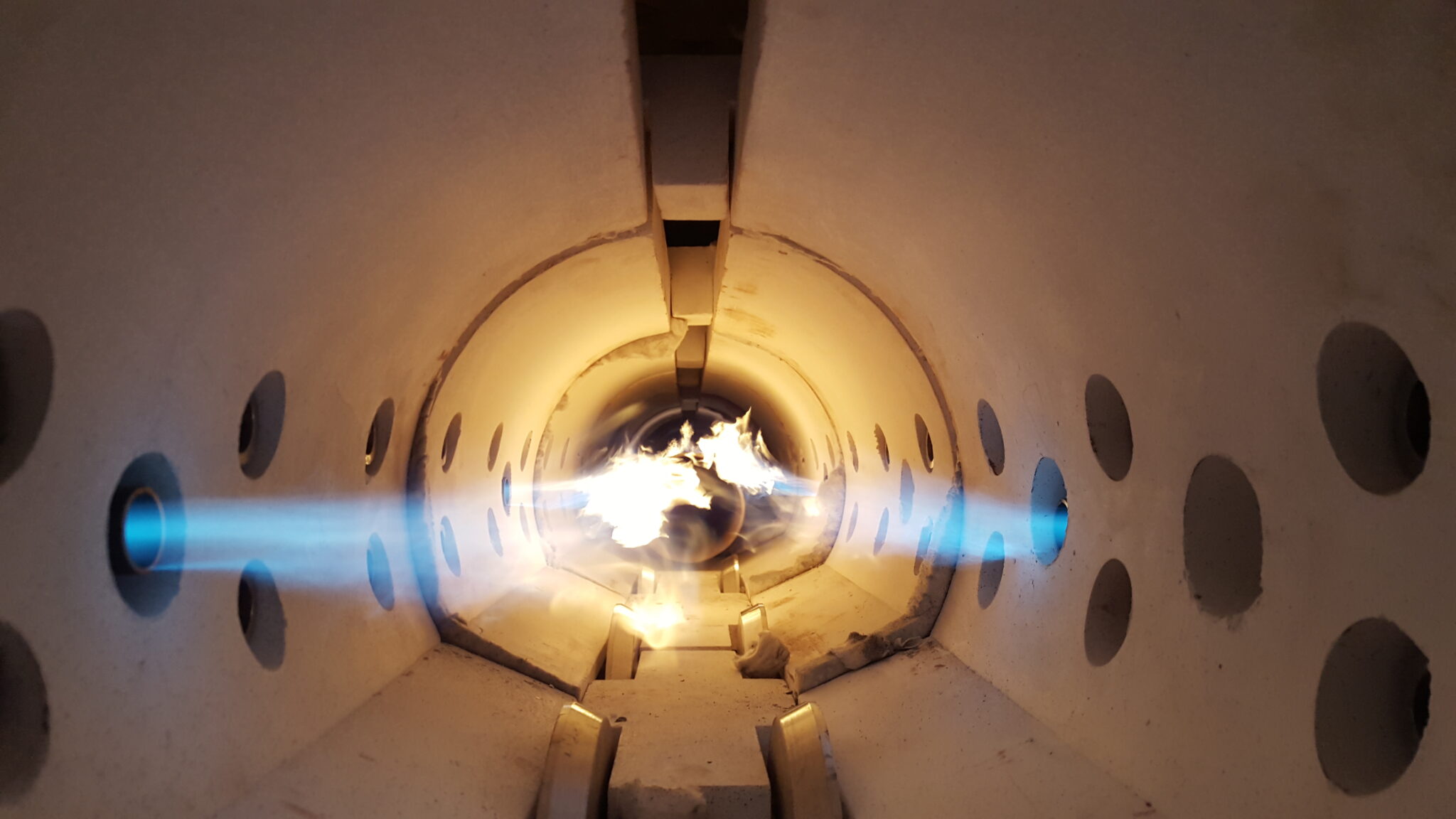

Sistem Teknik designs and manufactures furnaces for rapidly heating aluminum logs/billets prior to the extrusion process. These furnaces are direct gas-heated and have PLC-controlled pre-mix jet type nozzle burners. The logs/billets are heated quickly with low gas consumption (18 Nm3/ton Al.) thanks to the special arrangement of the burners.

The temperature is measured within a range defined by surface thermocouples that can be moved back and forth. Following the heating process, the desired material surface temperature remains within a +10 °C tolerance. Reusing flue gases generated in the preheating zone improves heating efficiency.

These furnaces are outfitted with low thermal mass insulation materials and easily replaceable refractory blocks for insulation. The use of insulating materials with low heat retention capacity prevents melting. The furnace transfer system, which includes a roller conveyor, is designed to work in tandem with the hot billet cutting machines. The front heaters and the last zone burners located at the furnace outlet can heat the first 200 mm above the set values (tapper heating).