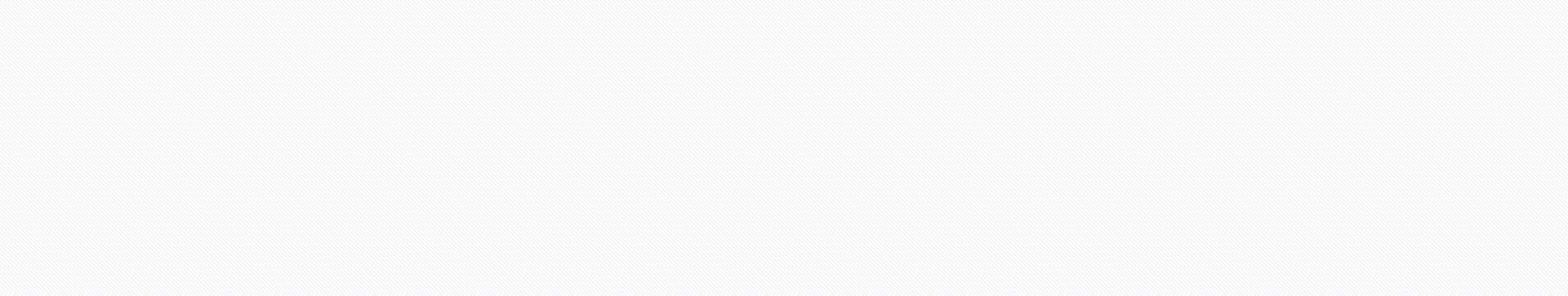

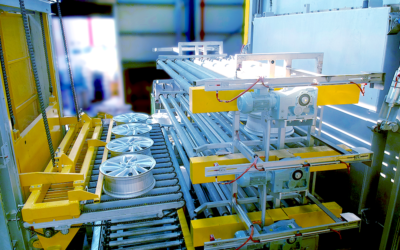

FULLY AUTOMATED PROCESS FLOW

optimum temperature homogeneity and 25% less energy use in continuous lines

Sistem Teknik creates continuous T-6 heat treatment lines for aluminum casting. Heat treatment includes a solvus curve, but the process also includes solution annealing, quenching, and aging. The average solution period varies depending on the material cross-section:

- Heating time: 1.5 hours from 20°C to 540°C

- 7 seconds of quenching (as the door starts to open)

Maintaining a temperature of 540 °C for 4-5 hours (the maximum furnace temperature is 650 °C)

The furnace elevator and door are designed to minimize the time lost between solution annealing and quenching. As fans continuously circulate the air inside the oven, the temperature homogeneity tolerance is +5 °C. Recuperative burners or hairpin resistors provide heating. The temperature homogeneity tolerance of the tank’s water is also +5 °C.

In the event of a drop in the water level, the tank’s water level can be controlled and an automatic water supply system triggered. The temperatures of the air and water in the furnace and water tank are continuously controlled and recorded in the SCADA system.