Degassing Units

We design and manufacture degassing units for molten aluminum refining from hydrogen, inclusions, and alkalis. Degassers are used in the log, coil, strip, rod, and small ingot casting lines. Excessive mixing and dross formation are avoided with the special bath design and the use of rotating nozzles. Metal remains at low levels inside due to shortened degassing periods, resulting in efficient processes.The degassing system removes hydrogen by purging argon through the rotating nozzles. Our customers can also receive a chlorine-based alternative system.

Sistem Teknik degassers can be easily installed in existing layouts without taking up extra space, and the system is available in both stationary and tiltable configurations. Stationary degassers have a rotating system that allows for easy maintenance.

Sistem Teknik stocks all degasser spare parts.

Specifications :

- 5-50 tons/hour capacity

- Immersion type heaters with two SiC heater elements in a Sialon protective tube

- Ar and N2 are the process gases (Optional Cl)

- Gas injection is accomplished via two graphite rotors (or more)

- The amount of aluminum left in the crucible after casting is 400-1350 kg.

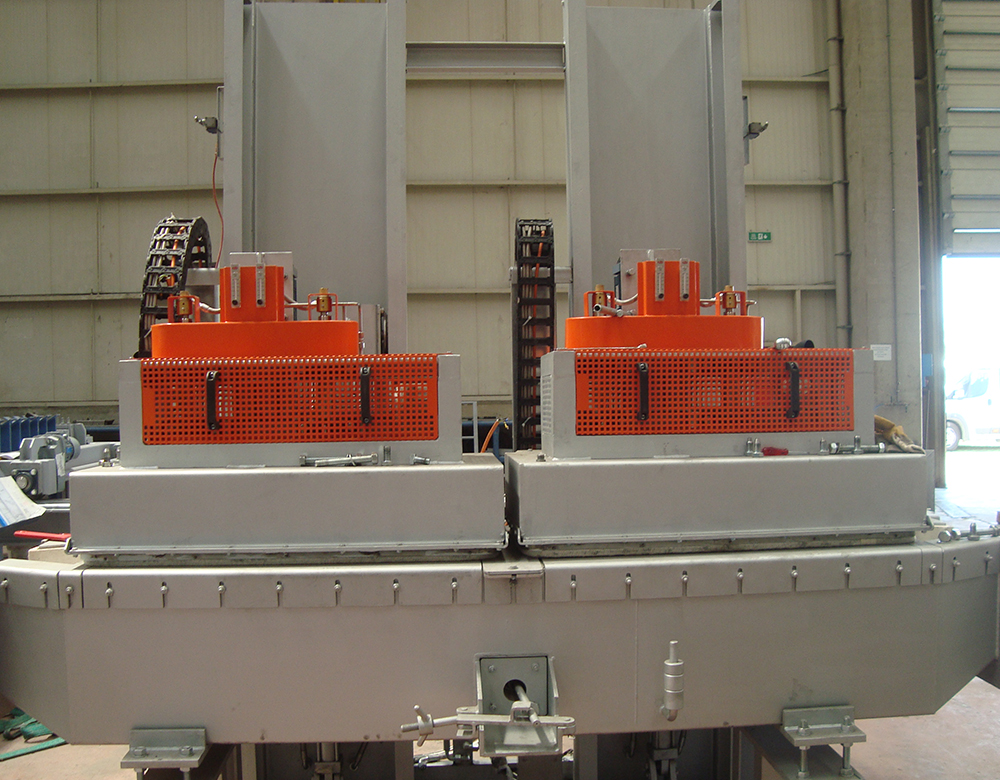

Ceramic Foam Filters

Sistem Teknik designs and produces ceramic foam filtering systems (CFF) in order to remove inclusions generated between the degasser and the casting system. CFFs prevent quality issues during downstream operations. The CFF design is made according to the application as both single chamber and double chamber options exist.

Features:

- Model: CFF & TCFF

- Filter sizes: Standard 7″ – 26″ (30-50 ppi)

- Capacity: 2-50 tons/hour molten aluminium.

- Heating: Flat flame burner

- Heating cover: Pneumatically-tilted

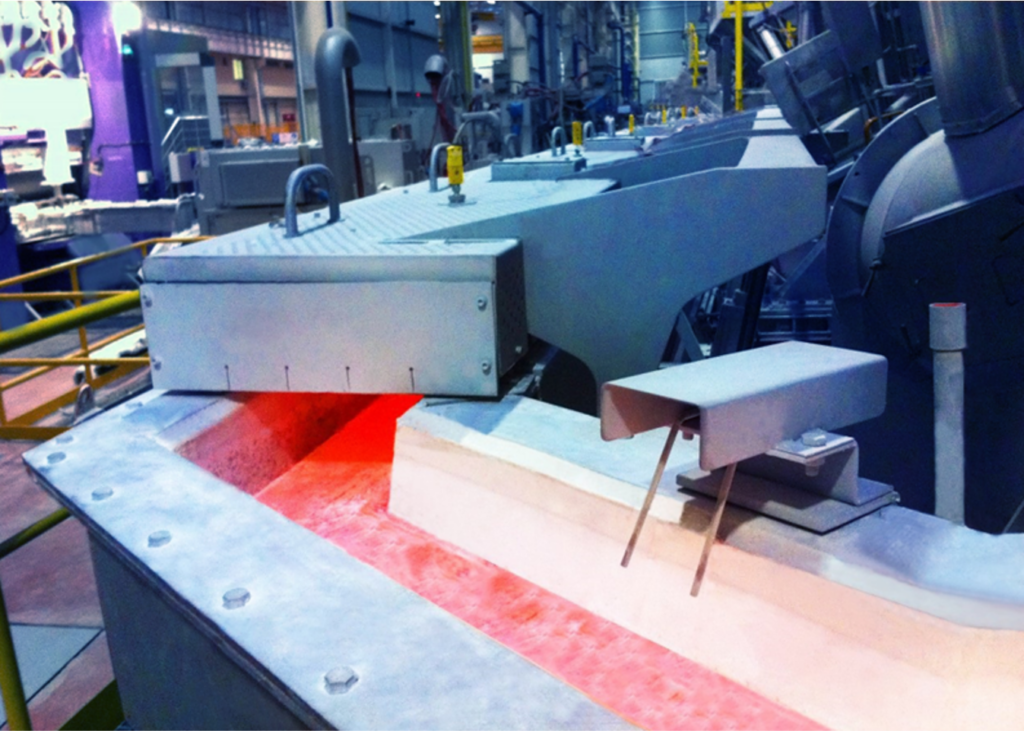

Heated Launder Systems

We design and manufacture electric or gas-fired launders for transferring molten aluminum between furnaces and casting machines. Electric-heated and insulated covers are used to keep the liquid metal temperatures constant during casting in systems that require low liquid metal transfer rates (continuous casting lines, wire rod casting lines, etc.).

The launder system is made of a strong steel construction that will last for a long time. To ensure quality and safety, multiple layers of insulating materials, including porous plugs, are used to ensure minimal thermal losses. Launders can be cleaned easily with the pneumatic actuation system used for covers.

Launder sizes range from 2 to 50 tons/hour and can be adjusted to meet the needs of the customer.

POROUS PLUG SYSTEMS

Sistem Teknik provides porous plug systems for new and existing furnaces to improve the mixing process and pre-degassing of aluminum before casting. As a result, by increasing heat transfer, the system improves cost-effectiveness. Inert gases are used to create an agitation effect and to degas the melt. Reactive gases, on the other hand, can improve or even enable refining processes. The control of the porous heads can also be programmed for different mixing algorithms using the individual gas flow mechanism.

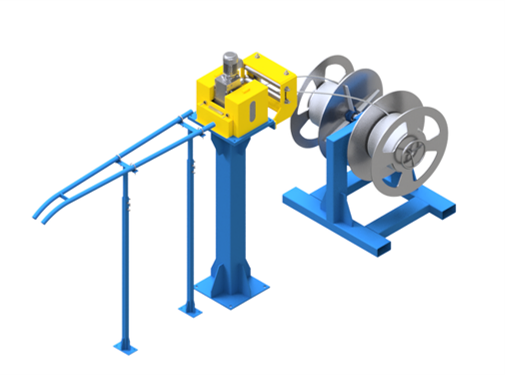

Electromagnetic Stirrers

Electromagnetic stirring and pumping systems for aluminum heat processing play an important role in improving cost-effectiveness and quality. Electromagnetic stirrers are safe and simple to apply to melting furnaces from the bottom or the side. Normally, molten aluminum cannot be continuously mixed because the furnace must remain open. Continuous stirring, as well as homogeneous temperature distribution and more effective aluminum alloying, are all possible with the electromagnetic stirring system. The oxide layer over the molten aluminum is not disturbed when the electromagnetic stirring systems are turned on. This drastically reduces energy consumption and dross formation.Sistem Teknik provides electromagnetic stirring solutions that are both air and water-cooled, and can be applied to new or existing melting/holding furnaces. If a transfer car is integrated into the casting process, a single electromagnetic stirrer can be used for two furnaces.Electromagnetic pumps are also available for single and multi-chamber furnaces. Electromagnetic pumps (water-cooled) with charge wells enable the recirculation of molten aluminum as well as alloying, allowing small shredded scrap and chips to be charged to side well furnaces and multi-chamber furnaces.